Ford is testing 3D printing of large scale car parts with the potential to improve fuel efficiency and offer greater vehicle personalisation.

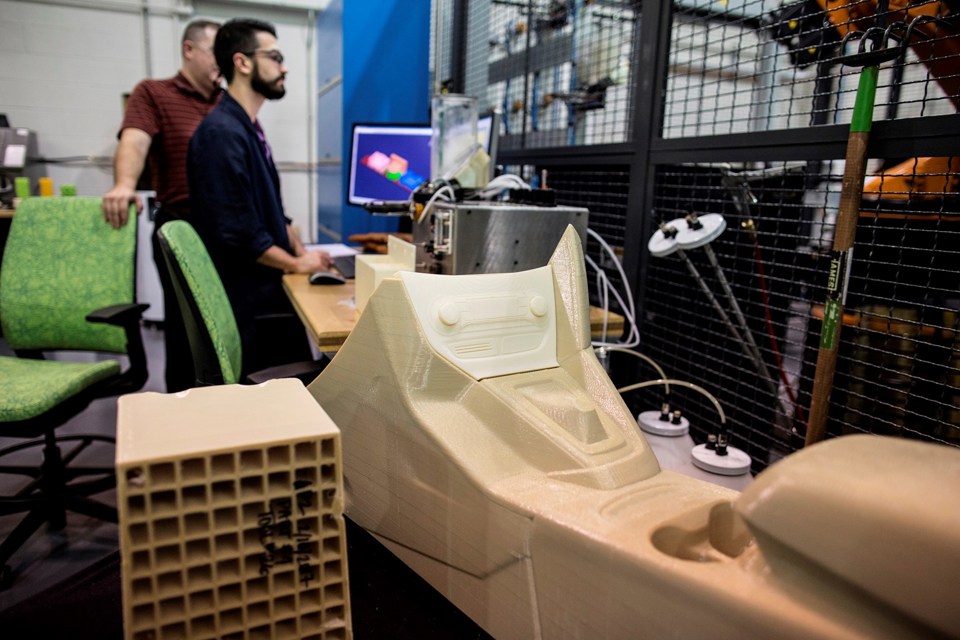

Using the Stratasys Infinite Build 3D printer, Ford can print car parts of practically any shape or length, the Stratasys Infinite Build system could be a breakthrough for vehicle manufacturing, providing a more efficient and affordable way to produce tooling, prototype parts, or components at lower volumes, like personalised car parts or specialised parts for racecars.

3D printing could have immense benefits for automotive production, including the ability to produce lighter-weight parts, which may help improve fuel efficiency. A 3D-printed spoiler, for instance, may have half the weight of its metal-cast equivalent.

“With the Infinite Build technology, we are now able to print large tools, fixtures, and components, making us more nimble in design iterations,” said Ellen Lee, Ford technical leader for additive manufacturing research.

The new 3D print system is located at Ford’s Research and Innovation Center in Dearborn.

Login to comment

Comments

No comments have been made yet.