This article has been taken from the latest Fleet News special report Electric Fleet: Taking Charge. It is sponsored by Allstar, Athlon, Northgate and Shell Fleet Solutions.

Transitioning vans to full electric is bringing a number of new challenges to fleet operators, many of which do not exist when using diesel models. In this feature we look at some of the common issues and how organisations are innovating to overcome them:

- 'Bricking' 12v batteries

- On-board power

- Efficient work-time charging

- Lack of workplace charging infrastructure

‘Bricking’ 12v batteries

PROBLEM: Modern electric commercial vehicles rely on an ever-growing number of auxiliary systems, such as telemetry and communications, to keep operations running smoothly.

However, some of these need power even when the vehicle is not being used, draining the 12-volt battery to the point when it become impossible to start or recharge – so-called ‘bricked’!

“There is then no choice but to return it to the franchised dealer and even then, it can often take weeks to resolve the problem,” says Paul Hollick, chair of the Association of Fleet Professionals.

SOLUTION: To overcome this issue, Centrica is prolonging battery life by using solar panels fitted to the roof of its electric vans.

“Vehicle downtime is bad for business and it’s bad for our customers,” says Rob Simister, director of fleet at Centrica.

“We had to find a solution quickly so we can make sure our engineers can get to our customers exactly when we’re needed most.”

The company worked with fleet technology specialists Genie Insights to have solar panels fitted to its vehicles.

These provide a trickle charge to the 12-volt batteries, keeping them operational even during periods of inactivity, or when a so-called ‘parasitic’ draw is being taken by ancillary equipment.

“We explored several options, but there was a clear frontrunner,” says Matt Harris, fleet engineering and innovation manager at Centrica.

“This partnership will equip all 2,500 of our electric commercial vehicles with the solar solution, ensuring the 12v batteries remain charged. As a result, our vans will stay on the road longer.”

On-board power

PROBLEM: Traditionally, employees such as engineers have had to run the diesel engine on their van to use a inverter/battery system to power tools and ancillary equipment – an option not available on EVs.

SOLUTION: Many fleets are looking at alternative zero-emission power sources, such as the Clayton Power LPS (Lithium Power Supply) system, which can be used instead of having a diesel engine running.

National Grid Electricity Distribution (NGED), for example, is investing £1.5 million in installing the Clayton Power system in all its Nissan Townstar, Škoda Enyaq and Isuzu D-Max commercial vehicles, to power tools, laptops and sensitive test equipment for cable networks.

“Using the Clayton Power LPS system in EVs not only allows us to run the auxiliary lighting systems, but it also allows us to operate an electric heater which is vitally important for keeping some of the jointing compounds and other materials to the required temperature,” says Jane Nicholson, fleet technical specialist at NGED.

“One of the main issues of moving to the transition of EVs is trying to find a vehicle we can run on pure electric but also do away with the diesel side of it and the engine idling.

“As a result, we’ve had to look at what we need to fit within this vehicle, but also providing an alternative charging facility within that, which is where the Clayton Power system comes in.”

The all-in-one battery unit can be charged from solar power or mains electricity, and provides users with access to 12V and 230V supplies.

Clayton Power says the 2kW battery can power, for example, a welder for 50 minutes, or an angle grinder for one hour and 40 minutes.

Fleets looking to transition to EVs are being urged to consider infrared heating to reduce the amount of energy needed to heat the interior of a vehicle.

Yorkshire Ambulance Service has fitted 35 electric patient transport ambulances with the technology, which is wired directly into the vehicles’ electrical systems, while power from solar panels on the roof covers 75% of the running cost.

The heating system is triggered by sensors, so it switches on only when someone is inside, and works in reverse to traditional heating methods by first heating the passengers and fabric of the vehicle, and then warming the air – a quicker and more efficient process. It provides up to 60% energy saving compared with traditional heaters, together with weight savings and less condensation.

“We strongly believe our patented vehicle heating system is the answer to help fleets going through the transition to electric, saving energy, cost, weight and improving passenger and driver comfort,” says Dean Allsop, director at Clayton Vehicle Systems, which developed the technology.

“We’d urge fleet operators and vehicle convertors to consider how their vehicles will be used and to look at ways to improve their operating efficiency, such as using infrared heating.”

Efficient work-time charging

PROBLEM: Centrica lists downtime as its main concern when it comes to charging its electric vans.

“The cost of a 40-minute charge across a fleet of 8,000 vans runs into tens of thousands of pounds when considering the negative impact on utilisation – far more than the kWh cost of the actual charging,” says Rob Simister, director, fleet operations at Centrica.

Openreach estimates it sees between 7% and 10% inefficiency across the working week due to drivers charging.

This downtime presents operation problems for fleets.

“One of the biggest challenges is how our engineers who use an EV can do a day’s work,” says Dermot Coughlan, fleet director at Kelly Fleet Services.

“For example, if a guy is supposed to do 10 jobs in a day, he may now be down to six as he’s got to spend time charging.

“So do we put another crew on to cover the extra work? Instead of having one van on the road, do we then have two? Economically, can you get that to work?”

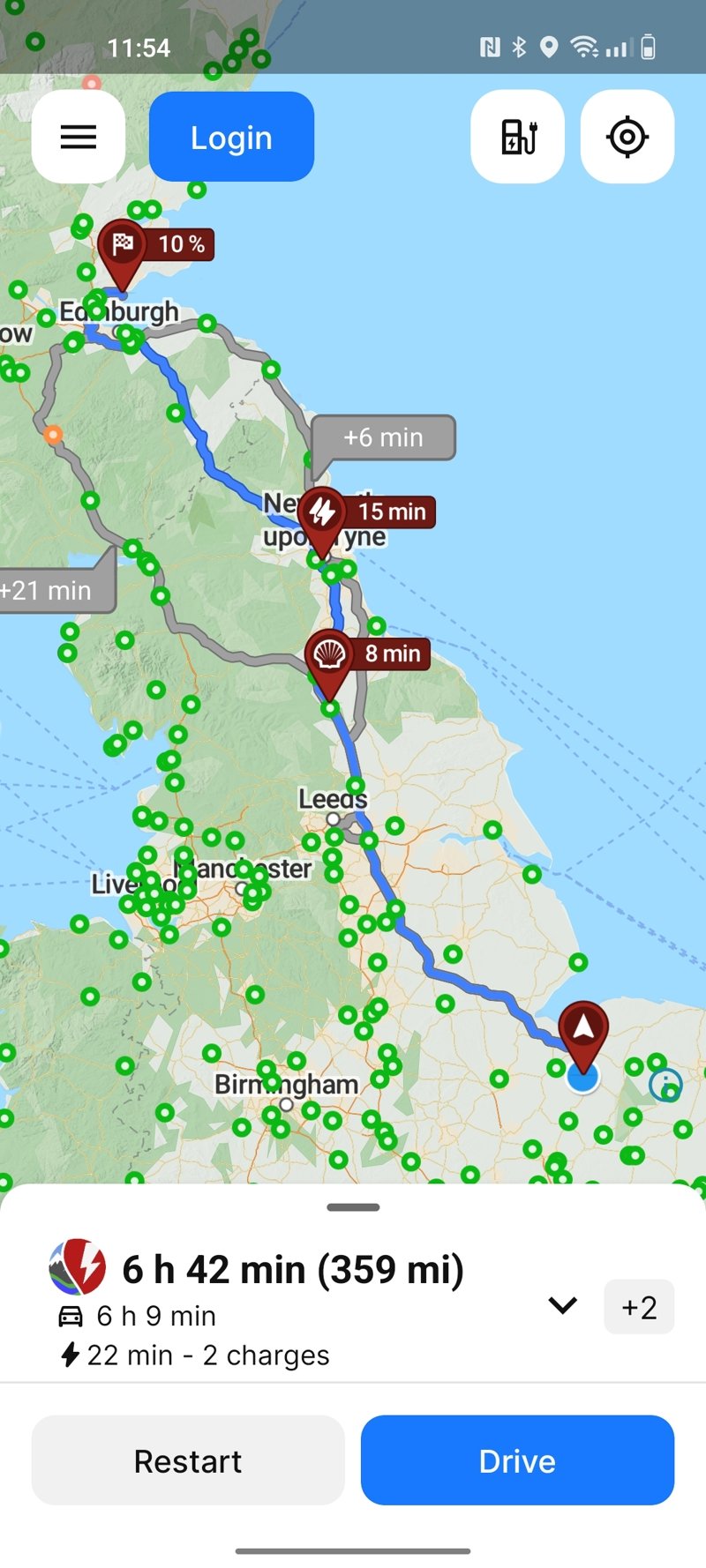

SOLUTION: Ovo Energy uses the free version of the A Better Route Planner smartphone app to inform drivers where they need to charge and how long for, minimising downtime and disruption to their working day.

“In that app you can input what vehicle you are driving, the load you are carrying, what the weather is like, how far you need to travel, what charge you need to get there, etc. – a whole raft of things,” says S-J Mitchell, senior fleet and supply chain manager at Ovo Energy.

“In that app you can input what vehicle you are driving, the load you are carrying, what the weather is like, how far you need to travel, what charge you need to get there, etc. – a whole raft of things,” says S-J Mitchell, senior fleet and supply chain manager at Ovo Energy.

“It will use this information and will tell you where to stop and how long for. It may say ‘stop here for 12 minutes and that will get you to X, where you can charge again for X minutes’.

“Most drivers will go ‘I’m not stopping for 12 minutes, I’ve got to stop for three hours’, but everyone who has used the app has got better efficiency, their range anxiety has disappeared, and they use it all the time now.”

Mitchell has worked with Ovo Energy’s planning and scheduling team to ensure they factor in the time drivers need to charge into their operations.

“We don’t treat the time drivers stop as dead time. We use that as a time for drivers to catch up on their paperwork or their emails,” she adds.

Lack of workplace charging infrastructure

PROBLEM: Although many van fleets operate back-to-base models in which vehicles are left overnight at a depot where they could be charged, some organisations are unable to improve workplace charging infrastructure due to an insufficient grid connection.

While this can be upgraded, the Department for Energy Security and Net Zero says the queue to do this has grown tenfold over the past five years, with some organisations facing a wait of up to 15 years for the work to be carried out.

“We cannot deliver net zero and improve air quality without decarbonising commercial vehicles,” says Mike Hawes, chief executive of the Society of Motor Manufacturers and Traders.

“But if operators have to wait up to 15 years just to be able to plug them in at their depots, there is no case for investment.”

Analysis by Tual, which develops swappable powerbanks and deployable charging solutions for EVs, found between 50% and 80% of sites looking to electrify have constrained or absent grid connections.

Tual estimates obtaining the grid upgrades typically takes between one and three years, with significant upfront capex required at an average of £500,000.

SOLUTION: Delivered in partnership with Wincanton, Connected Places Catapult and the Department for Transport, Tual has carried out a month-long trial of a battery-buffered DC charger.

The PowerUp charger draws and stores available grid power when most efficient, while renewable-power sources can be integrated to avoid the need for further battery storage.

The power can then be used as required, delivering charging at speeds of up to 120kW.

Deployed at a Wincanton site in West London, the PowerUp charger delivered an average of 4.9 high power DC charges per day, using an 11kW connection that previously delivered 1.2 low-power (AC) charges per day.

Contributing to Wincanton’s ongoing commitment to achieving net-zero operations by 2040, the PowerUp charger also facilitated 3,138 zero-emission miles during its four weeks in operation, saving 1,560kg of CO2 emissions.

“Solutions such as Tual’s are central to making our net-zero ambitions happen, and smart innovation is essential for helping businesses expedite the expansion of their fleet electrification, cost-effectively,” says Claire Charlton, head of innovation at Wincanton.

With the ban on the sale new petrol or diesel vehicles just one or two replacement cycles away, transitioning to an electric fleet is at the top of the agenda for the majority of fleet decision-makers.

But the switch to the zero-emission technology is fraught with obstacles – especially for van operators who face legislative issues as well as vehicle suitability and charging.

In out new Electric Fleet: Taking Charge report, we look in detail about how you can start the journey to van electrification and speak to those already well advanced in their transition about the innovative ways in which they overcome some of the problems.

Employing industry experts and scientific research, we also bust some myths about batteries – spoiler alert, the average level of degradation at 1.8% a year is much lower than many predicted - and look at the technologies poised to come to market promising greater range and faster charging.

The report is sponsored by Allstar, Athlon, Northgate and Shell Fleet Solutions.

Login to comment

Comments

No comments have been made yet.