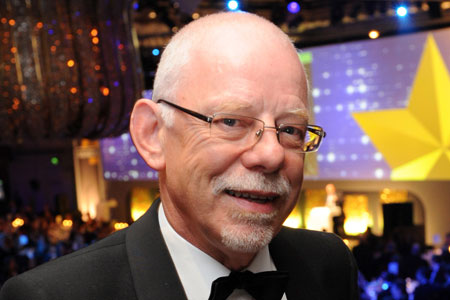

David Graham tells a story of his introduction to fleet management at E.On which rings true for many fleets, both large and small.

It relates to accurate data and the need for fleet managers and companies to hold all the facts about their vehicles in order to devise robust strategies.

“When I applied for the job I was told the company had 3,000 vehicles,” he says.

“It needed someone to pull the business and strategy together so I started to build a fleet list. It actually had 7,200 vehicles.”

This scenario is replicated in fleets the length and breadth of the UK – and probably globally.

The simple question of ‘how many vehicles do you operate?’ frequently results in guesstimates or a rounding up or down of the figures.

E.On recognised its shortcomings and put a structure in place to address them; many others are still operating in a data and knowledge void which restricts their ability to control cost.

Graham brought to E.On a career built on banking at Lloyds Bank and, latterly, leasing at Pendragon Contracts and Masterlease.

He spent five years at E.On before retiring last year, although he remains open to “fresh challenges”.

Fleet News: It took you around four months to establish exactly how many vehicles E.On was operating. What were the initial steps you took to control cost?

David Graham: I needed to establish lines into other departments in order to have a policy to address costs.

The lesson here is that fleet managers tend to be responsible for one element. For example, at E.On I wasn’t responsible for insurance.

A lot of the cost is below the line so I presented the financial argument for policy change.

I set the challenge for all line managers to show their budget lines that added up to the fleet cost.

They could only find two-thirds of the cost.

That’s because around a third of fleet cost is unmanaged as it’s no-one’s responsibility. This is where you have to assume ownership.

FN: And how did you assume ownership?

DG: By understanding the business objectives and impact on the vehicles and the expenditure.

For example, the environmental impact was a priority at E.On in 2007 so it’s about understanding how to bring that into the fleet policy.

If your priority is to reduce cost, which for many fleets it is, you have to understand the impact on cost of making changes, such as not replacing cars .

How does this impact on the grey fleet, on control and health and safety? Who is looking at all these areas?

As a fleet manager I have no power – it’s all about how I manage the stakeholders.

Fleet managers often under-estimate how much they can influence senior management by putting forward a well-structured, sensible argument.

Think about the fleet director; his job comes down to reducing cost.

So talking about spending money on telematics isn’t going to work.

But if the argument is about saving a certain amount of money over three years by making a small up-front investment you are more likely to win the case.

FN: Do you believe fleet managers feel comfortable in making a financial investment case to their board?

DG: I don’t think many fleet managers are comfortable sitting down with their finance director and having a meaningful conversation.

But we also need more people that have CPC qualifications and CIPS training that can manage suppliers and contractors. This will enhance their professionalism.

We have great people operating in fleet but I don’t see a structured and progressive training programme.

There are elements of it available but it almost stops at the vehicle level; it needs the strategic level, the broader management skills.

Fleet managers need to be able to read and understand a contract and go through the terms with their supplier. Often people haven’t had that conversation so they don’t understand the deal that was originally agreed.

Once you do, you can move on to more complex conversations on elements that should be in the contract, other SLA elements. The world moves on and contracts date.

FN: Isn’t this something usually controlled by a procurement team so fleet managers are kept out of the loop?

DG: Supply chain management is an area that some fleet managers don’t think is part of their responsibility. But how can you deliver value and savings without having knowledge of this area?

You don’t necessarily do it, you might have a procurement team, but you have to have a relationship with that team to be able to influence what happens.

FN: Grey fleet was an area you were addressing shortly before you retired. It’s an area that many fleets struggle to control, particularly in the heavily unionised public sector. Any advice?

DG: It is easy to find out how much money a company is spending and a fleet manager can help an organisation prepare for an HMRC audit by looking at the records and handling them.

Go to the unions and ask about their policy if staff want to claim grey miles. They will have policies. Tell them what you want to do: you want to protect their members. They will accept this.

Senior management want to see people that are trying to help the business by doing sensible things. And fleet is one of those areas where you can demonstrate to managers that you are doing the right thing.

FN: One of the biggest bellyaches we hear from fleet managers is about their drivers and how much they complain.

DG: The problem with fleet is that everyone is a driver. It’s like teaching – everyone’s been to school and thinks they know best. It’s the same with fleet.

The starting point with drivers is to recognise that they are intelligent and from where they are sitting their argument makes perfect sense. I had to understand that, then do the work to address the problem and feed back to them the outcome.

It’s also about having the right processes so you can say to drivers ‘if that happens this is what we recommend you do and this is the order you do it in because this aligns with our contract so our supplier is expecting these things’. But you have to make it easy for them – for example, having one contact number instead of 10.

Tell them the process and the pros and cons, where the options and breakpoints might be and the escalation process – i.e. what to do if what I say will happen doesn’t happen. Laying out the ground rules is the most effective way of doing things.

Graham believes there is “huge scope” to change the way fleets operate. He believes most organisations spend more than they need to; they don’t measure their fleet costs properly and they have misaligned policies and aspirations.

“Fleet managers are employed to deliver value first and foremost and it has to be perceived value from the business and the drivers through the contracts that you have,” Graham says.

“You have to constantly challenge what’s acceptable because the environment will always change.

“And if you continue to do the same things as you have in the past you will continue to spend the same amount of money.”

Fleet News Award winner career highlights

2007-2012 E.On fleet manager

2003-2007 Masterlease head of operations

1999-2003 Pendragon Contracts operations manager

Other previous positions

Evans Halshaw operations manager

Lloyds Bank – various roles

Login to comment

Comments

No comments have been made yet.