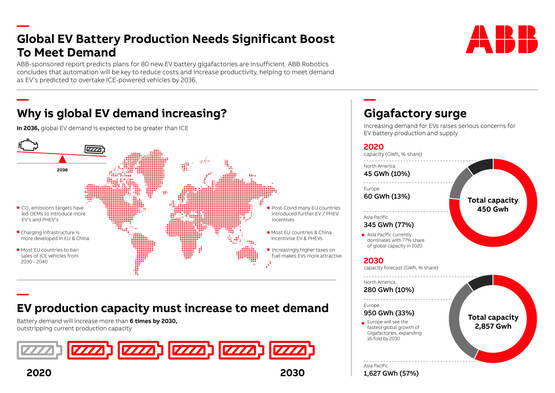

Plans to build 80 new electric vehicle (EV) battery factories globally will not be sufficient to meet future demand, according to a new report.

It is anticipated that sales of EVs will overtake those of internal combustion engine (ICE) vehicles by 2036, but the ‘Electric Vehicle Battery Supply Chain Analysis’ report from ABB Robotics and Ultima Media suggests that battery supply may pose a “serious risk” to the growth of electricity as a clean propulsion fuel.

The report outlines that although Asia leads EV battery production, Europe will make up vital ground over the next few years while US manufacturers are also planning increases in capacity. Researchers also outline the importance of battery pack assembly being located close to or within car assembly facilities.

“Co-locating battery pack assembly not only boosts sustainability by reducing transportation, it increases flexibility. A cellular approach to production is easily integrated alongside existing lines. If the demand curve moves, cells can be added or removed quickly to maintain accurate production scale,” said Tanja Vainio, managing director of ABB Robotics Auto Tier 1 Business Line.

He believes that building a robust battery supply chain will create a distinct competitive advantage for OEMs, setting a trend towards maximum production flexibility, whether battery pack production is insourced or outsourced, to further reduce costs and boost productivity.

With the high price of EVs still creating a barrier to further market penetration, reducing vehicle cost has become a whole-industry focus. EV batteries represent up to a third of total vehicle costs, therefore ABB is focused on solutions that improve battery manufacturing productivity.

“Increasingly we see that higher productivity and lower costs are driven by assembling battery cells straight into packs,” added Vainio. “ABB is working in partnership with a number of manufacturers, using its systems and knowledge to increase productivity, quality and safety levels, as well as reduce finished pack costs through automated assembly - vital if EVs are to meet their required cost and adoption targets.”

The ‘Electric Vehicle Battery Supply Chain Analysis’ examines the current and future state of EV battery supplies – sources of materials, technologies available, demand analysis and potential risks.

The full report is available to view here: https://new.abb.com/products/robotics/events/ev-battery-report.

Login to comment

Comments

No comments have been made yet.