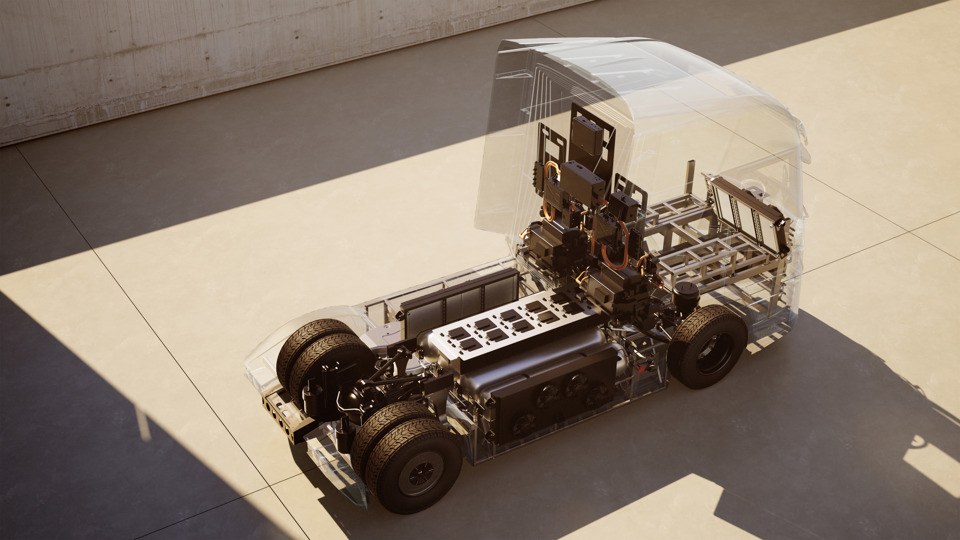

Hydrogen Vehicle Systems (HVS) has revealed a new modular design for its hydrogen-powered HGV, enabling fleets to configure the vehicle to meet specific needs.

It provides a hydrogen fuel cell powertrain with medium and high-power e-axles, up to three hydrogen tanks and two power outputs

HVS said the modular platform’s adaptability extends the vehicle's operational life, allowing for in-service upgrade and replacement of powertrain modules as technology develops.

The modular platform is built on a fixed wheelbase, which means the vehicle’s footprint does not change, irrespective of specification.

Pete Clarke, head of design at HVS said: “We’re offering maximum modularity within a single base vehicle platform, and we would never have been able to achieve this level of flexibility and optimisation with a diesel-powertrain derived vehicle design.

“Our vehicles have been created for a fundamentally different technology within an all-new package, so every cubic millimetre has been designed afresh. We initially calculated the maximum wheelbase possible to achieve the required turning circle and manoeuvrability for the target market. The design process then began with the optimal powertrain format, around which the vehicle design was then created – ensuring that form followed function.

“Rather than playing with a configurator, HVS can put the best value package together for customers based on information about what they do, the loads they will carry, along with their ranges and routes.”

Hydrogen Vehicle Systems (HVS) revealed its new long-range hydrogen-fuelled tractor unit at the CV Show. The truck has a range of up to 370 miles and a refuelling time of 15-20 minutes

Login to comment

Comments

No comments have been made yet.