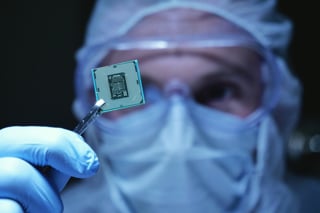

Hyundai is predicting that the global semiconductor shortage will ease from Q2, allowing vehicle production to rebound in the first half of this year.

The chip shortage has resulted in major car and van makers cutting production and left fleets facing long lead times for new vehicles.

However, Hyundai’s executive vice president Seo Gang Hyun painted a more optimistic picture last week. “The normalisation of auto chip supply and demand is expected in the third quarter, when the capacity of semiconductor companies is expected to rise,” he said.

The shortage will continue in the first quarter due to the spread of the Omicron variant, Seo told Reuters.

Southeast Asia is central to the supply of basic chips that drive the world's cars, smartphones and home devices, with Malaysia's chip assembly industry accounting for more than a tenth of a global trade worth more than $200 billion.

Hyundai said it expects a 20% sales jump in its biggest market, North America, in 2022.

Vehicle prices increasing

Analysts warn that soaring raw material prices, component shortages and logistical bottlenecks caused by the pandemic are likely to further drive-up costs in the current quarter.

Lee Jae-il, an analyst at Eugene Investment and Securities, said: “It is still difficult to forecast how the chip shortage will pan out ... also there will be other uncertainties involving the spread of the Omicron variant and potential issues related to Ukraine tensions.”

Toyota and Honda have said they plan to curb their production due to rising Covid-19 cases and part supply issues.

And as supply chain and distribution disruptions continue, delaying deliveries and production, analysts expect Hyundai to raise vehicle prices to mitigate the impact.

Last week, Mike Hawes, the boss of the UK’s automotive trade body, the Society of Motor Manufacturers and Traders (SMMT), warned of potential price rises for cars and vans.

Vehicle manufacturers are already facing a rise in the cost of materials such as lithium and cobalt, key to electric vehicle production, with some experts expecting this alone to be enough to push vehicle prices up as the car parc increasingly electrifies.

However, Hawes said that soaring energy prices could lead to increases in the price of new vehicles.

He explained: “If the semiconductor issue can be resolved, energy will be the most immediate and pressing challenge as we can see what’s coming down the line in terms of price increases.

“The margins on volume car manufacturers are wafer thin and energy will potentially be going up 50%, 60% or 70%.

“There were vehicle price increases last year and, like any other manufacturing sector, if you’re facing increasing input costs, it is going to pull pricing up."

Login to comment

Comments

No comments have been made yet.